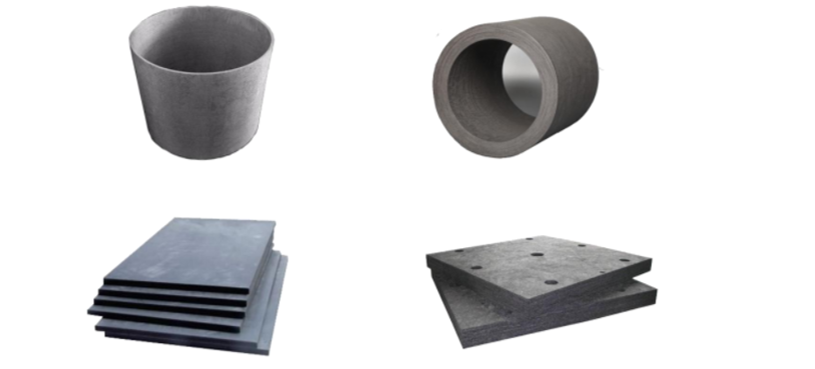

The hard felt composite thermal insulation material has the advantages of small thermal conductivity, excellent thermal insulation performance, uniform density, small amount of air release in vacuum environment, good heat shock resistance and corrosion resistance, no pollution to products and furnace cavity, saving effective space in furnace, convenient installation and maintenance, and can meet the needs of various monocrystaline furnaces and monocrystaline furnaces.

| Description | Standard Value | High purity |

| Processing temperature | 2200 | 2400 |

| Carbon content | ≥99.9 | ≥99.99 |

| Heat conductivity | 0.6 | 0.45 |

| Volume density | 0.16-0.18 | 0.16-0.18 |

| Compression strength | 0.73 | 0.71 |

| Bending strength | 2.52 | 2.5 |

| Ash content | ≤131 | ≤80 |

| Specification |

Customized as per drawings and requirements |

|

PAN-based graphite felt has high temperature resistance, corrosion resistance and low specific heat. Good heat insulation, small ash content, light weight and soft, with good shape retention performance. In the high temperature environment of vacuum or inert gas, the performance of thermal insulation material is superior and stable. It is an excellent thermal insulation material for monocrystalline and polycrystalline silicon ingot furnace, optical fiber and semiconductor resistance furnace.

| Description | Standard Value | High purity |

| Processing temperature | 2200 | 2600 |

| Carbon content | ≥99.9 | ≥99.99 |

| Heat conductivity | 0.44 | 0.3 |

| Volume density | 0.07-0.12 | 0.07-0.12 |

| Tensile strength | 0.45-0.68 | 0.45-0.68 |

| Ash content | ≤220 | ≤80 |

| Specification |

Length≤30m; width≤1.5m; thickness≤15mm |

|

Copyright © 2020-2024 Jiangsu R.R. Solar Energy Co., Ltd.